Double clutching and the synchromesh gear box in old cars

Double clutching, also called double de-clutching, is a technique for changing gear which helps the gears mesh together better and is therefore less likely to cause gear grinding and damage. It was in common use in manual transmission vehicles before the introduction of synchromesh gearboxes as used today. This page explains why it was necessary to double clutch in old cars and describes how to double clutch with explanations and diagrams of synchromesh gears and gear boxes.

____

By Neil Cryer - see sources

Why double clutch?

Double clutching was necessary in older vehicles with manual transmissions to avoid gear grinding and damage when shifting gears. The gear box sets how hard the engine has to work. For steady speed along a level road, the gear is set to the top level. For pulling away from stationary or going up a hill, it will be set to a lower value. This changing of the gear setting causes different gear wheels to be meshed together. If the two gears to be meshed are spinning at different rates and yet still forced together the result can be a nasty noise and damage to the gears. The double clutching process involves careful accelerator adjustment to try to get the two gears rotating at a closely matched rate.

Modern cars have what are called synchromesh gearboxes which have a technique to cause gears that are about to be meshed to syncronize with each other before engaging, thus causing a silent gear change and no noise.

How to double clutch

With a car with a manual gearbox, the right foot is used for the accelerator and brake and the left foot is used for the clutch.

In order to double clutch, place the left hand on the gear selector lever and the left foot on the clutch pedal. Depress the clutch pedal fully to disconnect the engine from the drive wheels. While the clutch pedal is fully depressed, move the gear selector lever into 'neutral' and then release the clutch pedal. This re-connects the engine to the gearbox which now has no gears meshed together.

Now press the accelerator to bring the engine up to the estimated speed it would need for the planned next gear. This speeds up the gears ready for them to be re-engaged. With the gears about to be engaged now spinning at the anticipated correct speed depress the clutch pedal and move the gear selector lever to the required position. This meshes the gears without any grinding noise as the gears being meshed are at the correct speed. Finally release the clutch pedal to complete the gear change.

Yes, the whole process does sound rather complex but I can assure you that it became second nature to those of us who had to use it, and, in practice, was a very rapid process.

My experience of double de-clutching

contributed by Jan Clifford

The above method was what I was taught when first learning to drive. Soon it became second nature for a gear change to take less than a second - even though, in my work, I was having to do it at the same time as being distracted by the responsibilities of driving a London bus!

What double de-clutching looked like

My father learnt to drive in the 1920s when there were no synchromesh gearboxes. Then, after years without a car, he got one again in the 1960s and used all the driving techniques that he had learnt all those years ago. It looked very strange indeed! Every time he changed gear he went into neutral between gears with a rapid wobble, wobble, wobble on the gear lever - until I stopped him and pointed out that he could change gear without the wobble, wobble, wobble as long as he depressed the clutch while doing so.

from the webmaster

Synchromesh gears

A synchromesh gearbox is a type of gearbox designed to make gear changing easier for the driver.

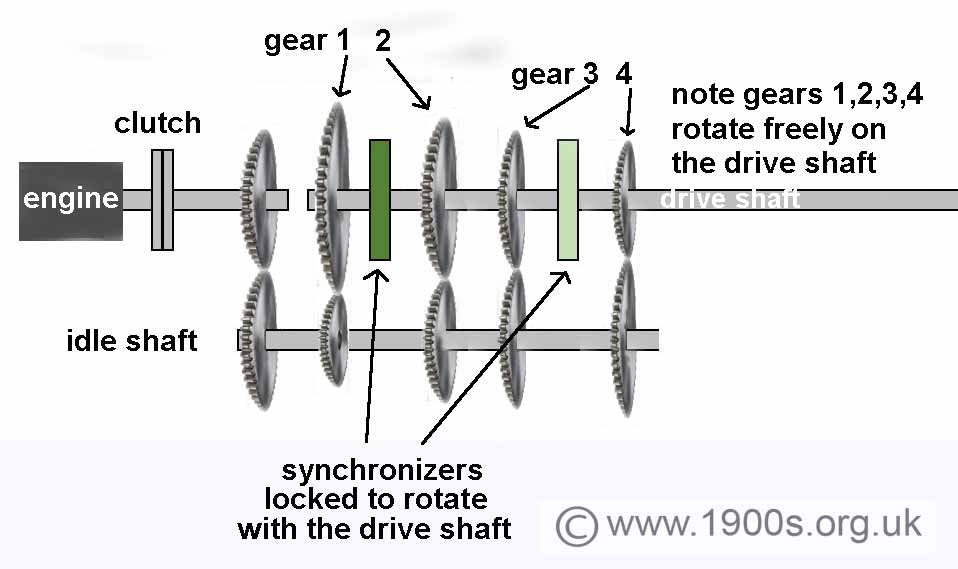

A simplified view of the layout of such a gear box is shown in Figure 1. While the clutch is not depressed, the engine is directly coupled to an idle shaft which holds four permanently connected gear wheels which therefore rotate constantly while the engine is running.

Figure 1. A synchromesh gear box in neutral showing all gears permanently meshed but no drive

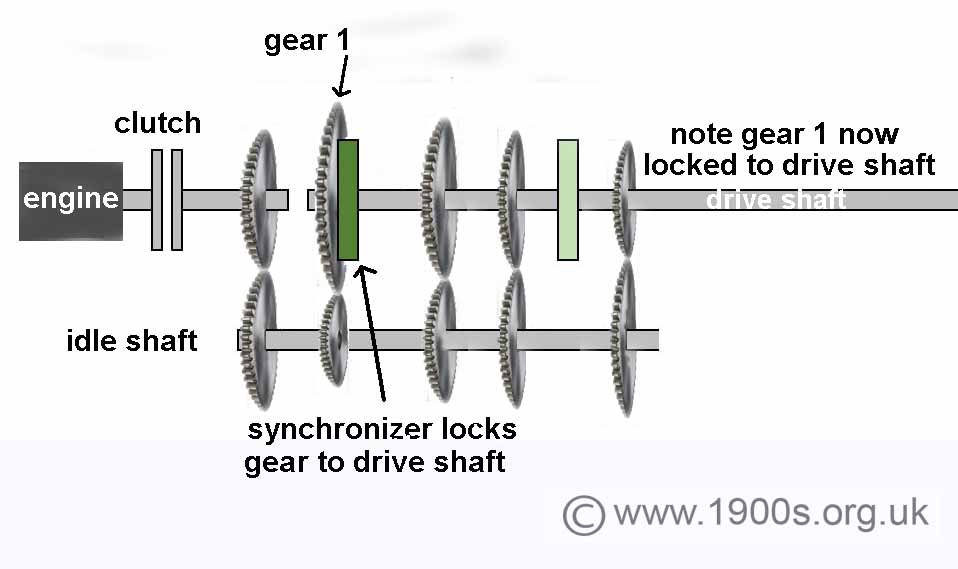

Alongside the idler shaft is the drive shaft which is connected to the vehicle's wheels. You will see that the drive shaft has four gears labelled gear 1,2,3 and 4 which are not coupled to the drive shaft and can rotate freely.

How does synchromesh work?

The clever working of the synchromesh gear box relies on the synchronizers, the green discs shown in Figures 1 and 2. These are permanently locked to the drive shaft while able to slide along it.

The gear lever causes a synchronizer to be pressed first gently and then locked hard against the required gear and in so doing locking the required gear to the rive shaft. In this way there is no possibility of gears clashing as they are all permanently meshed. It is clever way of locking just one gear at a time to the drive shaft that makes life so much simpler for the driver.

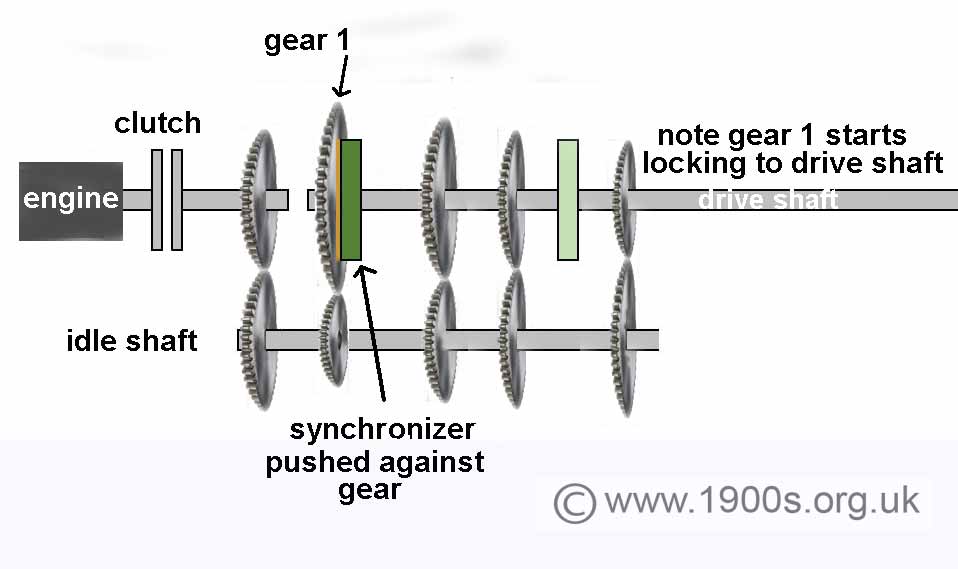

Figure 2. A synchromesh gear box showing the first gear in the act of engaging

Figure 2 shows the result of applying the clutch pedal which uncouples the engine from the gear box. If while the clutch is down the gear leaver is put into first gear, it will cause the synchronizer to be forced close to gear 1 as shown in the figure. The synchronizer is designed to cause friction when against a gear as illustrated with a faint green shading between the two.

The friction between the two causes gear 1 to quickly rotate at the same rate as the synchronizer. As the clutch is released the synchronizer is forced to lock with gear 1 thus coupling the two mechanically. As shown below in figure 3.

Figure 3. A synchromesh gear box showing the first gear fully engaged

This is the moment where the driver consciously releases the clutch gently so as to give a smooth increase of speed. The car is now in first gear.

The shift into gear 2 follows a very similar process, starting once again with depressing the clutch peddle, so causing the synchronizer to be released from gear 1 ready to cosy up to gear 2 when the gear lever is put into the second gear position. Third and fourth gear follow the same process but this time with a second synchronizer situated between gear 3 and 4.

| sources | webmaster | contact |

Text and images are copyright

If you can add anything to this page or provide a photo, please contact me.