Coal mines in the UK in the 1940s and 50s

Coal mining is the process of extracting coal from the ground; and there were (and still are) various ways of doing it depending on the depth of the coal, the technology available and legal constraints. This page is about deep UK coal mines in the 1940s and 50s. It considers their layout, the shafts and lifts, the staff, shift-working, the dangers and safeguards, working conditions and pay. It also includes a note about the end of deep coal mining in Britain. The distinguishing feature of the page is that the contributors are writing from experience, having themselves worked in a deep coal mine.

____

By Peter Dickens, former Bevin Boy miner and contributions from Bill Hogg, a former miner, with editorial work and research by the webmaster

Layout of a typical mid-20th Century UK coal mine

By the time of WW2, the remaining UK seams of coal were deep underground and were mined in what was called 'deep mines' or 'pits'. Essentially a deep mine consisted of a shaft or shafts down to the coal level and tunnels known as 'roads' leading off to spurs known as 'headings'. Both of these became longer as the coal was dug out and removed. Lifts carried the workers, their equipment and the coal output between ground level and the various entrances to the roads.

Mines were large places! Sometimes it could take as long as 20 minutes to walk along a road to the current coalface.

This image gives an idea of the length of the roads (corridors) in a mine. Although the lighting conditions are necessarily poor, by focussing on the central area, you can see that it is quite a distance away.

The coal mine where I worked as a Bevin Boy miner was Hern Heath Colliery which was fairly typical of other UK coal mines at the time.

Hern Heath Colliery as it was in the time of the Bevin Boys. Photo courtesy of the National Coal Board.

The shafts and lifts

The mine shafts and the lifts not only carried the miners, their equipment and the mined coal, they were also important aspects of the ventilation system, more of which below.

The mine where I worked had two pit shafts, known as the downshaft and the upshaft. Fresh air was carried down the downshaft and the stale air by the upshaft. The ventilation was so good that we sometimes felt quite cold when we stopped working.

My first few experiences of going down in the lift were quite dramatic because the lift seem to drop like a stone on its half-mile length of cable. Over such a long length, the cable had some flexibility, so that as the lift neared the bottom and the automatic brakes went on, it bounced up and down quite considerably. Fortunately it didn't take long to get used to this.

contributed by Bill Hogg, a one-time miner

In the mines that I knew, the lifts were known as 'cages'. The name was quite apt because the sides were made of strong mesh.

A mine lift, also known as a cage

Staff

People tend to think of the staff in mines as simply miners, but there were various types of worker all of whom contributed to getting the coal out of the ground and to the surface.

Officials

The pit officials were a manager, an under manager, overmen and firemen. All were qualified to use explosives and were required to carry a Davy lamp when in the pit to enable them to test that no gas was present. Anyone having shot-firing qualifications was able to use explosives.

The manager and under manager made regular visits to all pit locations but spent a large part of their working hours above ground. Both they and the overmen also carried powerful handlamps to enable them to see far ahead and into waste areas along the coalface.

Most underground activities were controlled by overmen and firemen.

Coalface workers

Workers at the coalface included loaders, drillers, cutters, conveyer movers packers and shot firers.

Crutters and rippers

Non-coalface workers included crutters and rippers. Crutters drove new roads through rock to enable new seams of coal to be reached and rippers maintained the height of the roadways by replacing roof supports as required.

Where necessary an official allotted jobs at the pit bottom. Bevin Boys were, at least initially, grouped with other workers working on haulage and sundry other jobs. The location of any job would dictate how long it would take to walk there.

Work shifts

There were three eight hour shifts daily, each having one short break in the middle.

The morning 'drawing' shift

The morning shift was called the 'drawing' shift and was when coal was removed from the mine. Miners called loaders were responsible for loading a length of the coalface and for the erection of the roof supports. Every coal face had a miner called an overman in charge. An under-manager would be in charge of every working section.

On the morning shift most of the workers would normally be either coalface workers or auxiliaries. Auxiliaries was the name given to haulage personnel who might be stationed anywhere between the pit bottom and the hopper where the tubs were loaded.

The afternoon and night shifts

The afternoon and night shifts were for preparing the coal faces for the morning 'drawing' shift.

The coal faces were hives of activity during the afternoon shift. A coal cutting machine, somewhat like a huge chainsaw, was used to undercut the seam for the whole length of the face. Holes were then drilled for shot firing.

The packers packed rubble and waste rock into the space vacated by the coal, so helping to hold the roof up.

Afternoon and night shifts worked from Sunday to Thursday so that preparation was made for the Monday morning shift.

Weekend work

Planned maintenance work, i.e. non-emergency work, was carried out over weekends.

The variety of my work

When I first came to the pit I worked initially on the day shifts. I was given no fixed activity and worked wherever I was sent on arrival at the pit bottom. The work could be on any part of the haulage system.

A job that I and others hated was the unpopular one of servicing what was called 'the plough'. It was a piece of metal placed obliquely across the bottom of the belt conveyor to scrape off any debris that had become stuck to the belt. My tasks could also be other ancillary work on or off the coalface.

After several months of working on the dayshifts, my back was injured in a shotfiring accident. Although it didn't seem too much to worry about, I was taken to hospital for treatment and told to go back for a check-up a week later. At the end of this period, I was able to resume work but was placed on the night shift, on which I remained for the rest of my time as a Bevin Boy.

On the night shift the work was more interesting. Firstly, I worked mainly with a pair of rippers although only on manual loading work. I also assisted the fitting of replacement arched supports in the roadways. This work was still on the minimum wage basis although the rippers were paid piecework. Often they passed me some 'beer money' on pay day.

After a few months, I was instructed to work with a conveyor fitter who was without an assistant that night. As we got on well together, he asked the overman if I could be his regular mate. So this became my nightly work for the rest of my time in the pits. It was mainly to extend the belt conveyor and check the face shaker conveyor to check that it was ready for the day shift. At the end of my employment, I was allowed to deputise for my mate with another helper on the few occasions he was away from work.

Dangers and hazards

Deep mines have always been hazardous environments. Major hazards included fire, flood, noxious and inflammable gas, explosion and roof collapse.

Personal injury could take many forms and was particularly dangerous because the lengths of the tunnels and the depth underground meant that access to medical attention could take a considerable time.

Safety and the size of mines and pits

contributed by Bill Hogg, one-time miner

Mines and pits varied in size and capacity with about 10 to 20 men in small mines to hundreds in some of the larger pits. Whereas it was relatively easy to get people out of a small mine if there was a problem, it was very difficult and time-consuming to get them out of the larger pits quickly. There may only be one main shaft with a winding engine and double cage system which can only extract a limited number of men on each lift.

Safeguards

To minimise danger, numerous regulations were in place from the various Coal Mines Acts and other documents on work in the mines. These were particularly concerned with ventilation, use of explosives, use of electricity within the mine, first aid provision and health and safety.

Ventilation

Ventilation was of prime importance to ensure good working conditions. Air circulation was achieved with fans from the downshaft and back up the upshaft going through all the main roads and workings. Normally all roads had two exits but where new headings were being created, this was not the case. So there were limitations on the numbers of workers allowed in the headings.

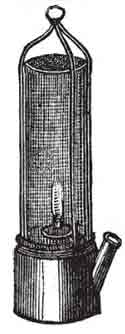

The miners safety lamp

An enormous improvement in mine safety was due to Humphry Davy who invented the Davy safety lamp in 1815. This proved the end of animals and canaries being used to detect gas before the human nose could do so. The sketch shows the lamp.

Miner's safety lamp/Davy safety lamp

The lamp is an oil lamp with a wick which is lit. The flame from the wick is totally enclosed in a metal mesh with holes which are too small for flames to pass through. This reduces the danger of explosions in the presence of flammable gases while the flame changes colour to alert miners to the presence of hazardous gas.

However, an improvement as the lamp was, it did not mean that mining was totally safe in deep mines in the early-mid 20th century.

The value and limitations of the safety lamp

contributed by Bill Hogg

Although the invention of the Davey Safety Lamp was such a big step forward in the increased safety against gas explosions in mines, it in did not stop mine explosions. In particular, some miners continued to use a candle because a candle gave slightly better light.

Accidents in mines in the 1940s and 50s

A note from the webmaster

I well remember as a child in the 1940s listening to the radio, the wireless as it was then called, and hearing daily bulletins on the ongoing successes and failures to get miners out of pits after rock falls deep underground. Sometimes it took two or three days to get the trapped miners back to the surface.

Frank Dibna in one of his television programmes quoted that before 1920 one miner was killed every 6 hours. Presumably safety had improved by the 1940s.

The check on which miners were still underground

Miner collecting his disk on the way into a mine.

A miner's disk. Photographed at a show in poor light. Do you have a better photo?

All miners were issued with a metal disk with an engraved number, known as the Lamp Number. Mine was 73. Every miner exchanged his numbered disk for a safety lamp at the start of his shift. The numbered disk remained on its hook until it was exchanged for the lamp at the end of the shift. The disks on the hooks thus represented all the workers who were still underground.

My experience of being trapped in a mine

I had one very unpleasant experience. The previous shift hadn't been able to clear all their working, and I was told to go with one other person to load tubs in a new heading. Headings have only one exit. While loading the tubs there was a fall which blocked this exit.

We knew that there was nothing for it but to sit it out and wait to be dug out, but while we were waiting the roof continued creaking. This made us acutely aware of the half mile of rock above us which we feared might not stay in place.

Fortunately we were not short of air, and other miners had heard the fall. So we only had to wait a few hours for them to dig us out.

Working conditions

Miners worked a five-day week with an eight hour shift each day.

In general, the work was not uncomfortable. I was lucky that our pit generally had wide and fairly high tunnels so that we could walk upright. There were times, though, when we had to work in a kneeling position with our backs to the roof.

Dust could sometimes be a problem but was usually minimised by the excellent ventilation. At that time, stone dust was more of a worry than coal dust. Miners with health problems were usually those who had had many years working in bad conditions.

Lavatory facilities

contributed by Bill Hoggr

For lavatories, miners used the niches in the sides of the passages which had been made primarily for them to back into while wide machinery was passing - rather like the niches that one sees nowadays in railway tunnels. It was simple to dodge into one of these for relative privacy. Fortunately the ventilation system was excellent throughout mines and anyway, by the next day, with the coal face having moved on, a new niche would be the target.

Normal lavatory facilities were impractical because the coalface moved forward about 6 feet every day.

Bath and shower facilities

Bath and shower facilities were provided but they were inadequate for the numbers of workers. So together with other miners we Bevin Boys had to use the bath and shower facilities at an old disused pit some miles away. We travelled there from our lodgings and changed into our working gear. We were then transferred by covered lorry to the pit head. At the end of our shift, we were taken back again and, after showering and changing, we returned to our lodgings.

contributed by Bill Hogg

Not all mines had bath and shower facilities or enough of them. My neighbour used to come home black with coal dust from a mine in Scotland.

Pay

At that time, coal mining embraced varied types of work with various rates and structures of pay. Many workers were paid on piecework rates and were remunerated according to a variety of measurements such as weight, yardage, number and size of roof supports fitted and number of shot holes drilled or fired.

As a Bevin Boy in 1944, I would have been paid less than the career staff. My pay was £5 per week. So they would have been paid fractionally more than that.

The end of deep coal mines in the UK

Following moves towards cleaner fuels, there are no longer any working deep coalmines left in the UK. Its coal reserves are, however, still considerable.

| sources | webmaster | contact |

Text and images are copyright

If you can add anything to this page or provide a photo, please contact me.